The Material Footprint of your e-waste

Understanding the environmental impact of the products that we buy is a key consideration in our current environmentally conscious world. We care more now about the impact that our buying behaviours have on the Earth. Whether it’s choosing products in recycled packaging or buying organic vegetables, knowing the impact of our supermarket purchases is fairly easy. But how do we know the environmental effects of our electronic equipment?

Material Footprint: The anatomy of your IT

A product’s material footprint is an indicator of its lifetime carbon footprint. It allows you to consider all of the carbon emissions required for the production and use of your products. For example, the material footprint of a car takes into account not only the fuel consumption of the car itself, but also the carbon footprint of the raw materials required in its production. This includes the carbon emissions from the mining of the iron ore and from the steel production factory among other factors. Ultimately, it is an indicator of the strain put on the environment throughout the lifecycle of the product.

Why is the Material Footprint Important?

Knowing the environmental impact of your buying behaviour is no use if you can’t make improvements. By understanding how your IT is produced, you can take the necessary steps to lower your material footprint. You have several options to improve your own material footprint with regards to your IT.

Reduce your carbon emissions

The first way to lower the material footprint of your IT devices is to limit the carbon emissions from their operation. This means making the switch from non-renewable energy to renewable energy. This switch limits the material footprint of your IT over its lifetime at your company.

Purchase low polluting products

The second option is to purchase products that have little impact on the environment in their production. This means selecting products which use recycled raw materials, or which have lower specs and thus lesser material requirements. This helps limit the environmental impact of the raw materials needed.

Re-use and Re-manufacturing

The final and easiest option is to extend the lifecycle of your IT. This means that your IT can stay on the market for twice or even three times as long as it would normally. Using second-hand IT instead of new IT reduces the strain on raw material production.

Global Material Footprint Statistics

The total global material footprint rose from 43 billion tonnes in 1990 to 92 billion tonnes in 2017 – an increase of 113%. This highlights our increased reliance on raw materials in recent years. This is expected to grow to 190 billion tonnes by 2060 if there is no rigorous political action taken.

What is e-waste?

E-waste or electronic waste is created when an electronic product is discarded after the end of its working lifecycle. The term e-waste covers almost anything that is powered by electricity. This includes PCs, laptops, smartphones, cameras among others.

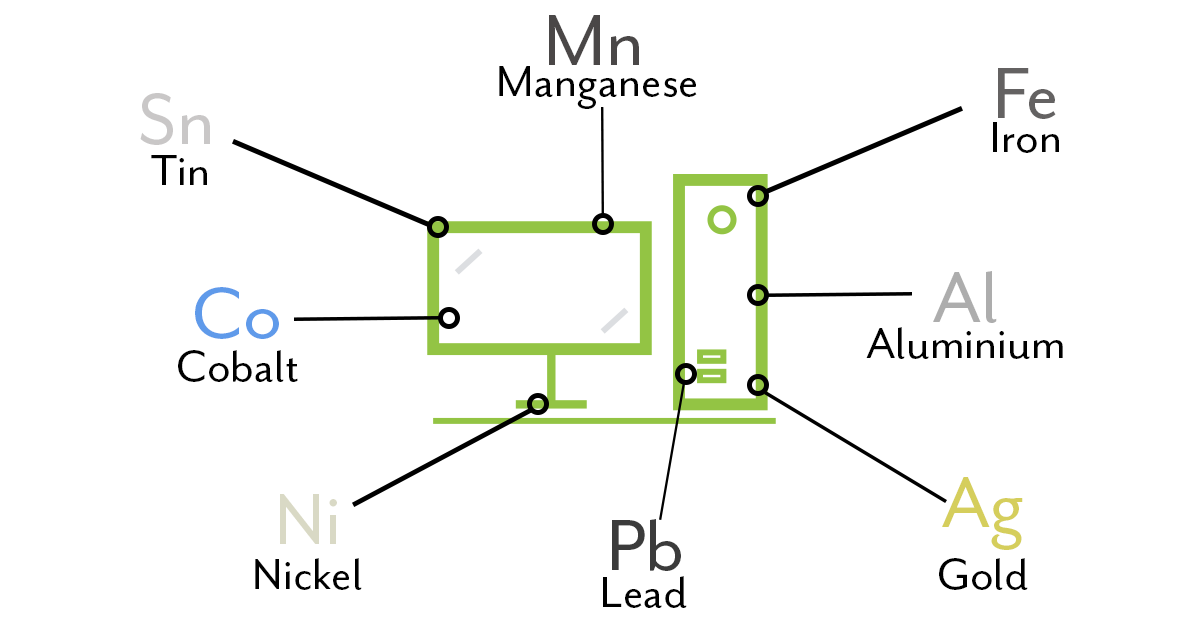

It is important to make a distinction between e-waste and everyday waste. E-waste can be particularly dangerous due to the toxic chemicals used in their production. This can lead to these hazardous metals leaking when they are sent to landfill.

What the Material Footprint means for e-waste

Our consumption of electronics is increasing while product lifecycles shorten, leaving a mountain of e-waste in our wake. E-waste is now the fastest growing waste stream worldwide, increasing by 38% since 2010.

This means that our material footprint is increasing as we continue to purchase new products which use critical raw materials such as tantalum and cobalt. Mining these raw materials causes a huge amount of pollution.

Limiting Your Impact

Research has shown that UK households and businesses produce 1.45 million tonnes of electrical waste each year. The e-waste research organisation Material Focus calculates that at least 500,000 tonnes of the waste were thrown away, stolen, or hoarded. Its latest study suggests un-recycled household electricals cost the UK over £370m a year in lost materials like gold, copper, aluminium, and steel.

By re-using these critical materials, through recycling and re-use, you can limit the carbon footprint of your IT estate. Specialist e-waste disposal companies are able to give these materials a second lease of life on the market. This lowers the lifetime material footprint of your IT. Other steps to limit your impact include:

- Try not to update your electronic equipment with every new release, wait until your electronics are reaching the end of their life cycle before replacing them.

- Repair your items before resorting to discarding of them straight away.

- Donate or sell your items if they are still in working condition to extend their life.

Why is it Important to Recycle e-waste?

It is important to recycle and discard of your e-waste in the correct format as most electronic products contain some form of toxic materials such as mercury and lead. These materials can negatively affect the environment. Also, this can cause high levels of air, soil, and water pollution.

Companies are constantly seeking to reduce the amount of waste they send to landfill. Policies which tackle e-waste specifically stop e-waste from being dumped in landfill where toxic materials can spread into the soil. Eventually, these traces of toxic materials pool into the ground below the landfill which has severe environmental consequences.

The more E-waste and metals that resort to landfill the higher the trace of these toxic materials will show up in the groundwater.

How Re-Tek are Combating the e-waste Crisis

Re-Tek was founded on the core principles of the circular economy and at the heart of our processes is the desire to extend the lifecycle of all products that we process.

Re-Tek actively work to get as much value as possible from each item of equipment. Ensuring to get the most from an item is critical for the environment and extends the lifecycle ICT through repair, refurbishment, and reuse activities. If we cannot repair an item, or it is not economical to do so, functional parts are harvested before being responsibly recycled.

Re-Tek aims to be a zero waste to landfill company. This is being carried out by ensuring re-use of equipment. Re-Tek diverted approximately 700 tonnes of equipment from both landfill and recycling (markets) in 2017, which equates to a significantly reduced environmental impact.

Finally, Re-Tek have been recognised for our best practice in the industry – achieving the “Remade in Scotland” award from Made in Scotland and the “Sustainability” award from CeeD Scotland.