How much Carbon does your IT really emit? A Brief Explanation of Embodied Carbon.

The embodied carbon of your electronic equipment is the sum total of the energy required to manufacture a product. You can better understand the full environmental impact of your purchases by understanding this. Below, you can find out how embodied carbon can be calculated and what it means for the environment.

A Lifetime of Carbon Emissions

When talking about the environmental impact of our daily commute, we only talk about the carbon emitted from our car’s exhaust pipe. Likewise, we talk about how the switch to electric cars would reduce the carbon emissions from our commute. However, this only takes into account the operational carbon emissions from the fuel used to power our cars. We don’t consider the carbon emissions from the manufacturing plants for both types of car. And what about the energy needed to mine and refine the raw materials? This is what we call embodied carbon. This can alter the way we think about the environmental impact of our purchases.

What is Embodied Carbon?

Embodied Carbon, sometimes known as Embedded Carbon, is a calculation of the carbon emissions from the manufacturing process. Ultimately, this means that there are other factors to the carbon emissions that come from your purchases. For example, the amount of tantalum required for 1,000 printed circuit boards creates 301.6kg of greenhouse gases (CO2-eq). Each of these printed circuit boards would be used in a PC, which adds to the carbon footprint of the final product. Therefore, the full environmental impact of your PC goes beyond its energy use. If you sum together the footprint of each component, you will have the material footprint of one PC. Multiply this out for a suite of 2,000 PCs and laptops and you can begin the see the full impact of your IT suite on the environment. Is there a way to limit this environmental impact?

How we can Harness Embodied Carbon

Once a PC or laptop has been manufactured and distributed, the majority of its carbon footprint has already been accounted for. This is the energy from the material mining, the manufacturing process, and the delivery to your facility. You begin to add to that material footprint through the energy required to run them. Many companies have realised that they can lower their operational carbon emissions by making some key changes. These changes include using renewable energy or switching machines off when not in use.

However, you can still make the most of the energy used to manufacture the product. You can do this by re-using the product itself or any of its composite parts. This gives these materials a second lease of life and reduces the material footprint of new products. Additionally, using second-hand IT lowers the material footprint of your IT estate as these products have an extended lifetime.

Calculating the Embodied Carbon of your IT

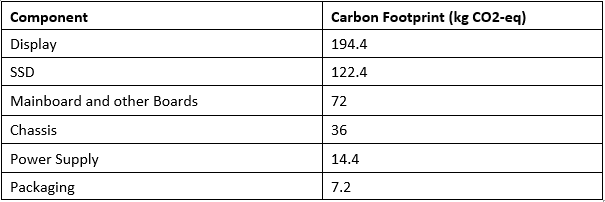

Calculating the total embodied carbon of a PC or laptop is not easy. Due to the number of different materials and components in these devices, keeping track of the carbon emissions for everything can be tricky. Therefore, getting the most accurate result would require a database of each different element with their specific carbon footprint. However, this would be very difficult to achieve. Alternatively, manufacturers will provide a breakdown of the key carbon footprint of each aspect of a PC. For example, the table below shows the values for a Dell Optilex 7760 All-in-One Desktop:

From this, you can calculate that the Dell Optilex 7760 All-in-One has an embodied carbon of 446.4kg CO2-eq. Over the course of a typical 4-year lifecycle, this accounts for around 62% of the total carbon footprint of the product with the remainder coming from the use of the product. Carbon footprint assessments for other Dell products can be found here.

A Little Perspective

200 Dell Optilex 7760s would create the same amount of carbon emissions as a full Boeing-747 travelling from London to New York over a 4-year lifetime.

Improving the Carbon Footprint of your IT

With this knowledge of the material footprint of your IT, you can begin to lower the environmental impact of your IT estate. Firstly, by extending the use period of these devices you could lower the overall impact of a PC or laptop. This is because over half of the carbon footprint of a device comes from the initial manufacturing rather than the use. This means that switching to renewable energy only tackles a small proportion of the problem. Extending the lifecycle of these PCs would flip this on its head. Using a PC over a period of 8 years would cause approximately 1,000 kg CO2-eq compared to using a PC over 4 years causing 720 kg CO2-eq.

A Better Way to Track the Material Footprint

Keeping track of the carbon footprint of a device over its lifetime remains difficult. This is particularly true when the product has been repaired using new components. Introducing a Digital Product Passport could be the solution to this problem. This would create a centralised bank of information for each device. This information would include the carbon footprint of each component within the device. By using this technology, you would be able to understand the full extent of the embodied carbon in your devices at the touch of a button.