Waste Hierarchy- The Inverted Pyramid

Waste Hierarchy- The Inverted Pyramid

What is the Inverted Pyramid?

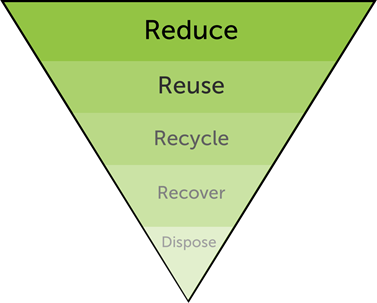

The inverted pyramid that shows the most important areas of sustainability at the top, with the least important at the bottom. The hierarchy allows us analyse our relationship with waste and how we can effectively tackle the battle in a sustainable way.

This pyramid is used to show how we tackle waste, as shown in the diagram above, Reduce is the most crucial way to tackle the global waste problem. In contrast at the bottom of the pyramid we have Dispose which is the least productive way to fight waste. By disposing of waste without much thought it can cause more harm than good as there are certain goods that need to be disposed of correctly, if not they can be harmful to the environment.

Components of the Inverted Pyramid

Let’s take a look into the key components of the pyramid in more detail to gain a better understanding of how this approach will tackle the fight against waste.

Reduce

The concept of Reduce is to reduce the amount of non-sustainable materials used in products by finding alternatives. For example, using paper bags instead of plastic bags and finding “green” alternatives to key materials used to create products.

Reuse

Reuse means using second- and rather than going straight to new items. An example is buying second-hand clothing instead of new, by doing this you are using products that have already been manufactured. By re-using items, it allows for be less wastage forced out into the environment as well as it being a cheaper alternative in the majority of cases

Recycle

Recycling is turning old products into something brand new. In our sector, it means taking the metals out of your mobile phones so that they can be used for making new products. There is a slight downfall to this as this component does use a lot of energy which is why Reuse is the preferred option.

Recover

Recover is associated with energy recovery. It means turning waste into energy such as burning biomass to create heat. This is something Re-Tek stand by as we have a Biomass Boiler which heats the whole facility. As well as making the use of solar panels to create energy to power the facility.

Dispose

The last area that we want to avoid at all costs, disposal means putting waste into the ground in landfill. It should only occur when all other options have been exhausted and there is no other way.

Waste Hierarchy and the Circular Economy

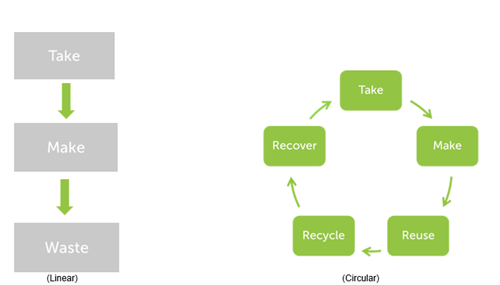

The two go hand in hand as they are both models that have the outcome to be beneficial to our environment. They both have the objective to reduce the overall waste output. The Circular Economy has the main goal to extend a product’s lifecycle, and to keep it in the economy for longer. This is done by finding alternatives to immediate dispose after it is no longer needed by someone or a business.

The diagram below shows the difference between how the Linear Economy model compares to the Circular Economy model.

As a society, we currently, generally operate within the Linear Economy, we are trying to move towards the Circular Economy as a whole, as we are realising the positive potential it has in some aspect of the supply chain throughout all industries.

Recent News

Even More Awards for Re-Tek

Even More Awards for Re-Tek

Re-Tek (UK) Ltd are thrilled to share that we have been awarded a 4-star rating at the Zero Waste Awards 2021.

Why Re-Tek was Awarded a 4 Star Rating

Re-Tek was awarded 4 stars due to the conscious efforts of our reuse rate of equipment throughout the facility which reduces our overall wastage output. Cardboard boxes are reused by our despatch team to limit our reliance on energy-intensive cardboard recycling, and our office equipment is second hand to stop equipment needlessly being recycled. Used coffee grounds are used by employees to fertilise home gardens and our employees are encouraged to separate their personal waste.

An element that stood out to the judging panel was our 83% re-use rate on all devices with the remaining 17% being recycled in line with the WEEE directive.

The Award Ceremony

The Award Luncheon was held on Friday 19th November at the Skyloft, Millbank Tower in Central London which was hosted by LetsRecycle.com.

This event allowed us to network with companies who operate within different industries, as well as learning processes businesses are taking to tackle the the issue of waste locally and globally.

Keynote speaker Anna Willetts, Senior Vice President of CIWM gave her perspective on the issue of Waste which gave a different insight to the topic.

Looking to the Future

With the recognition of this rating, we are continuously looking at our practices to identify how we can be even more sustainably efficient internally as well as externally. As a company we already working on ways on how we can achieve a 5-star rating in the future.

Even More Awards for Re-Tek

This Award is the second award received by Re-Tek in under 2 months. In September we won “The Best Circular Economy Company” at the CRN Awards.

These awards are attributes to Re-Tek’s commitment to the Circular Economy and extending the life of electrical products in an sustainable way.

Re-Tek is constantly seeking ways to improve daily operations to ensure we are providing the best service we possibly can to our customers, which we will continue to do throughout our practices.

Recent News

What is Digital Agility? 3 Key Benefits to a Digital Transformation Strategy for your Business

What is Digital Agility? 3 Key Benefits to a Digital Transformation Strategy for your Business

What is Digital Agility?

Digital Agility is all about adaptability. It requires businesses to quickly update or change their processes when they need to. It requires consideration of every part of the IT function, including hardware and software.

Sometimes known as Digital Transformation, Digital Agility pushes for digital innovation. It forces companies to evolve their digital strategies to reach desired outcomes.

Growing Trend or Fruitless Fad?

Like all new business strategies, digital agility has its supporters and its critics. Whether you are for or against it, the International Data Corporation (IDC) think it is here to stay. Their forecasts show digital agility spending reaching $1.97 trillion in 2022. This is an annual increase in spending of 16.7 percent from 2017 to 2022.

What are the Benefits of Digital Agility?

Having read about digital agility, you may be wondering “why should I care about this?”. There are several key benefits to digital transformation.

Increase your Adaptability

Your business can benefit from being more capable of adapting to market changes. A digital agility strategy means that most of the hard work is already done. That means that you can react swiftly to market changes. This helps keep your business running smoothly for your employees and customers.

A Boost to your Competitive Advantage

Innovation is key to building sustainable competitive advantage. Digital transformation can therefore be an asset for your company. Putting in place these processes has been shown to improve productivity, profitability, and to reduce costs. Embracing change can be the difference between leading your market and falling behind your competition.

Streamline your Processes

Digital transformation uses automation to review and clean data. You can then bring together data in an easy to access and organised way. This makes it easy to identify market trends and areas for improvement.

How do I become Digitally Agile?

Now that you know the benefits of digital transformation, you might be wondering where to start with it.

Below are a list of the key considerations for those moving towards a digitally agile way of working.

Drive Home a Digital Culture

Embedding a digital culture is the first hurdle that you will need to overcome. Convincing senior managers of the benefits of digital transformation isn’t easy. Then, you need to secure company buy-in. Otherwise, your digital strategy will likely fail at the first big market change.

This also means embracing change so that you are ready to adapt to, or even capitalise on, market changes.

Building the Right Processes

Advanced analytics and cognitive computing are just two ways that data can be used to drive business decisions. Setting up these processes takes time at first, but will save time when key decisions need to be made.

Keep your Data Clean

Reviewing the quality of your data is essential when becoming digitally agile. This means removing any incomplete or corrupted data. Failing to do this could mean you make bad decisions following large market changes. It is therefore important to set up some automation to consistently review data and sort inconsistencies

How has Covid-19 affected Digital Agility

The pandemic has forced businesses to reconsider how they make decisions. The sheer amount of change needed in a short period of time put the spotlight on digital transformation. Never before had companies of all sizes felt so much pressure to make their business models fit changing requirements.

55% of companies say the pandemic has resulted in permanent changes to their organisational strategy.

Changing Market Landscape

Businesses have already made changes to their strategy. Sixty percent of businesses say that Covid-19 has forced them to adapt their change management processes. Cloud-based activities have also seen a large uptake, with 64% of businesses making these changes. We’re living during a time that demands rapid change, quick launches, and innovative solutions, and many companies have already taken the first steps to achieve this.

How can IT Asset Disposal help with Digital Agility

IT Asset Disposal should be a key consideration for your business when moving towards a digitally agile strategy. IT Asset Disposal can ensure that you can make IT changes faster. It will allow your company to recover some of the value from redundant IT.

Changing IT Requirements

Digital transformation means new technological and software needs. That also means that your IT suite will need to change too. IT asset disposal can help return some of the value from your old IT assets when you need to upgrade your equipment.

The Material Footprint of your e-waste

The Material Footprint of your e-waste

Understanding the environmental impact of the products that we buy is a key consideration in our current environmentally conscious world. We care more now about the impact that our buying behaviours have on the Earth. Whether it’s choosing products in recycled packaging or buying organic vegetables, knowing the impact of our supermarket purchases is fairly easy. But how do we know the environmental effects of our electronic equipment?

Material Footprint: The anatomy of your IT

A product’s material footprint is an indicator of its lifetime carbon footprint. It allows you to consider all of the carbon emissions required for the production and use of your products. For example, the material footprint of a car takes into account not only the fuel consumption of the car itself, but also the carbon footprint of the raw materials required in its production. This includes the carbon emissions from the mining of the iron ore and from the steel production factory among other factors. Ultimately, it is an indicator of the strain put on the environment throughout the lifecycle of the product.

Why is the Material Footprint Important?

Knowing the environmental impact of your buying behaviour is no use if you can’t make improvements. By understanding how your IT is produced, you can take the necessary steps to lower your material footprint. You have several options to improve your own material footprint with regards to your IT.

Reduce your carbon emissions

The first way to lower the material footprint of your IT devices is to limit the carbon emissions from their operation. This means making the switch from non-renewable energy to renewable energy. This switch limits the material footprint of your IT over its lifetime at your company.

Purchase low polluting products

The second option is to purchase products that have little impact on the environment in their production. This means selecting products which use recycled raw materials, or which have lower specs and thus lesser material requirements. This helps limit the environmental impact of the raw materials needed.

Re-use and Re-manufacturing

The final and easiest option is to extend the lifecycle of your IT. This means that your IT can stay on the market for twice or even three times as long as it would normally. Using second-hand IT instead of new IT reduces the strain on raw material production.

Global Material Footprint Statistics

The total global material footprint rose from 43 billion tonnes in 1990 to 92 billion tonnes in 2017 – an increase of 113%. This highlights our increased reliance on raw materials in recent years. This is expected to grow to 190 billion tonnes by 2060 if there is no rigorous political action taken.

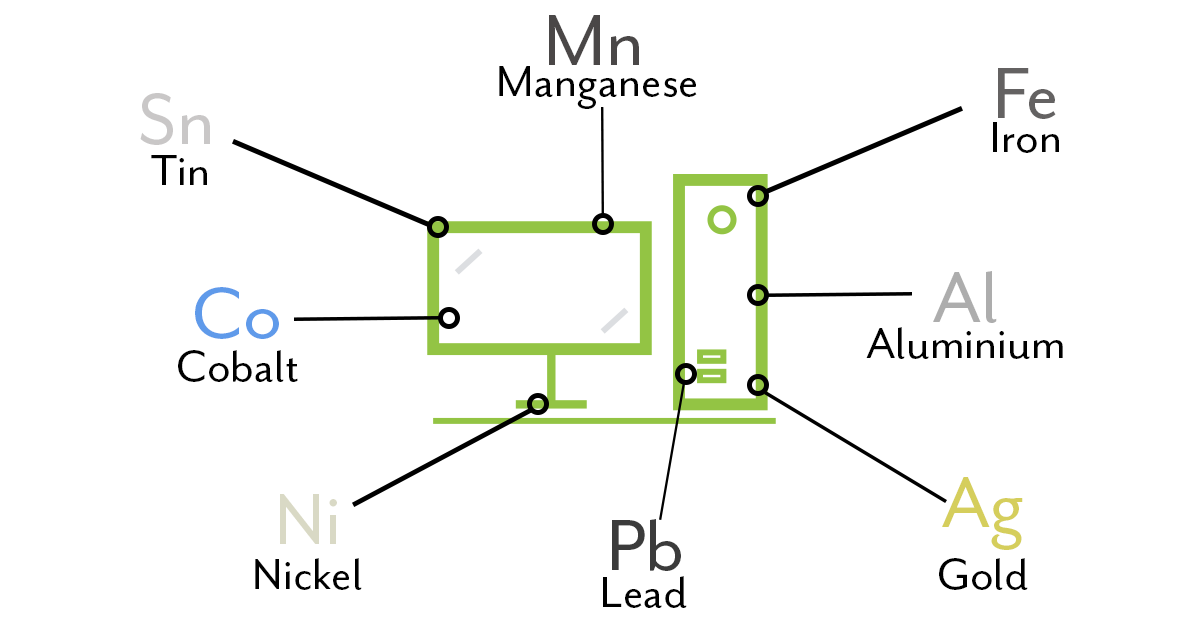

What is e-waste?

E-waste or electronic waste is created when an electronic product is discarded after the end of its working lifecycle. The term e-waste covers almost anything that is powered by electricity. This includes PCs, laptops, smartphones, cameras among others.

It is important to make a distinction between e-waste and everyday waste. E-waste can be particularly dangerous due to the toxic chemicals used in their production. This can lead to these hazardous metals leaking when they are sent to landfill.

What the Material Footprint means for e-waste

Our consumption of electronics is increasing while product lifecycles shorten, leaving a mountain of e-waste in our wake. E-waste is now the fastest growing waste stream worldwide, increasing by 38% since 2010.

This means that our material footprint is increasing as we continue to purchase new products which use critical raw materials such as tantalum and cobalt. Mining these raw materials causes a huge amount of pollution.

Limiting Your Impact

Research has shown that UK households and businesses produce 1.45 million tonnes of electrical waste each year. The e-waste research organisation Material Focus calculates that at least 500,000 tonnes of the waste were thrown away, stolen, or hoarded. Its latest study suggests un-recycled household electricals cost the UK over £370m a year in lost materials like gold, copper, aluminium, and steel.

By re-using these critical materials, through recycling and re-use, you can limit the carbon footprint of your IT estate. Specialist e-waste disposal companies are able to give these materials a second lease of life on the market. This lowers the lifetime material footprint of your IT. Other steps to limit your impact include:

- Try not to update your electronic equipment with every new release, wait until your electronics are reaching the end of their life cycle before replacing them.

- Repair your items before resorting to discarding of them straight away.

- Donate or sell your items if they are still in working condition to extend their life.

Why is it Important to Recycle e-waste?

It is important to recycle and discard of your e-waste in the correct format as most electronic products contain some form of toxic materials such as mercury and lead. These materials can negatively affect the environment. Also, this can cause high levels of air, soil, and water pollution.

Companies are constantly seeking to reduce the amount of waste they send to landfill. Policies which tackle e-waste specifically stop e-waste from being dumped in landfill where toxic materials can spread into the soil. Eventually, these traces of toxic materials pool into the ground below the landfill which has severe environmental consequences.

The more E-waste and metals that resort to landfill the higher the trace of these toxic materials will show up in the groundwater.

How Re-Tek are Combating the e-waste Crisis

Re-Tek was founded on the core principles of the circular economy and at the heart of our processes is the desire to extend the lifecycle of all products that we process.

Re-Tek actively work to get as much value as possible from each item of equipment. Ensuring to get the most from an item is critical for the environment and extends the lifecycle ICT through repair, refurbishment, and reuse activities. If we cannot repair an item, or it is not economical to do so, functional parts are harvested before being responsibly recycled.

Re-Tek aims to be a zero waste to landfill company. This is being carried out by ensuring re-use of equipment. Re-Tek diverted approximately 700 tonnes of equipment from both landfill and recycling (markets) in 2017, which equates to a significantly reduced environmental impact.

Finally, Re-Tek have been recognised for our best practice in the industry – achieving the “Remade in Scotland” award from Made in Scotland and the “Sustainability” award from CeeD Scotland.